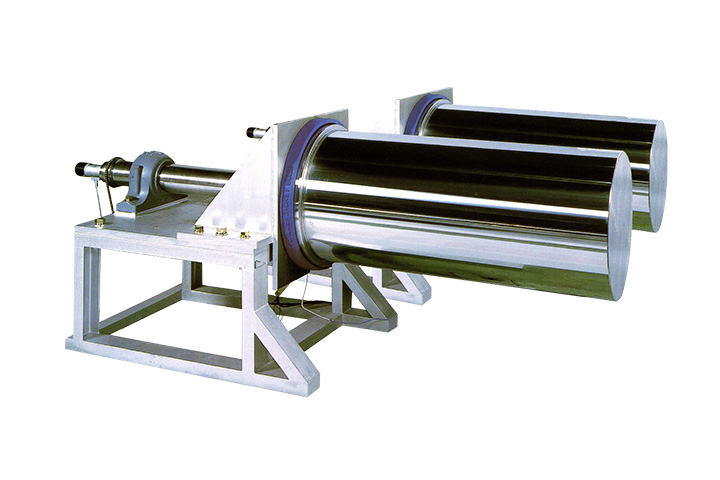

Induction Heated Jacket Rolls

High-Precision Thermal Processing Made Possible by Homegrown Technologies

Our proprietary induction heating technology enables the Jacket Roll to heat itself. The roll surface temperature is controlled within a ±0.5°C deviation by the jacket installed in the roll shell, enabling thermal processing with high accuracy.

This technology allows manufacturers to produce uniform products.

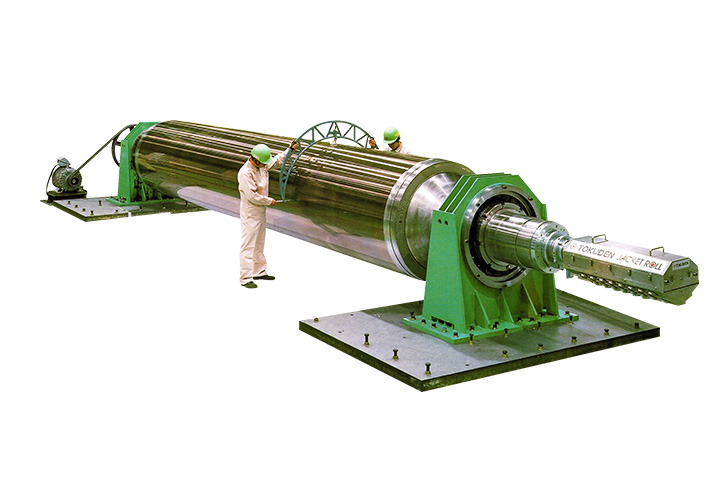

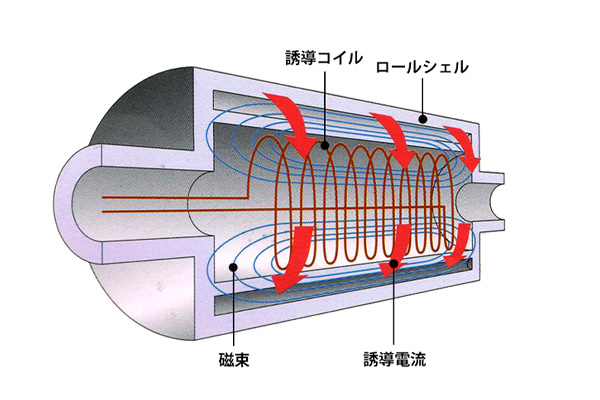

Structure of Induction Heated Jacket Rolls

Connected Jacket Chambers ensure

uniform surface temperature

Thermal media evaporate and condense repeatedly inside the dozens of vacuumed spaces (Jacket Chambers) inside the roll shell. The roll shell absorbs and disperses the thermal energy created by these reactions, resulting in a uniform temperature on the roll surface.

A shell that

heats itself

Magnetic flux occurs when an alternating current is provided to an induction coil. This induces a current on the inside of the roll shell, and the resistance heat causes the roll shell to generate heat. High-temperature thermal energy is achieved from the direct generation of heat by the roll shell itself.

An involute core

keeps power loss to a minimum.

Cores made up of a collection of strips of insulated magnesium formed into an involute shape greatly reduce iron loss (heat generated by the core itself that cannot be used effectively). This technology also keeps power loss to a minimum.

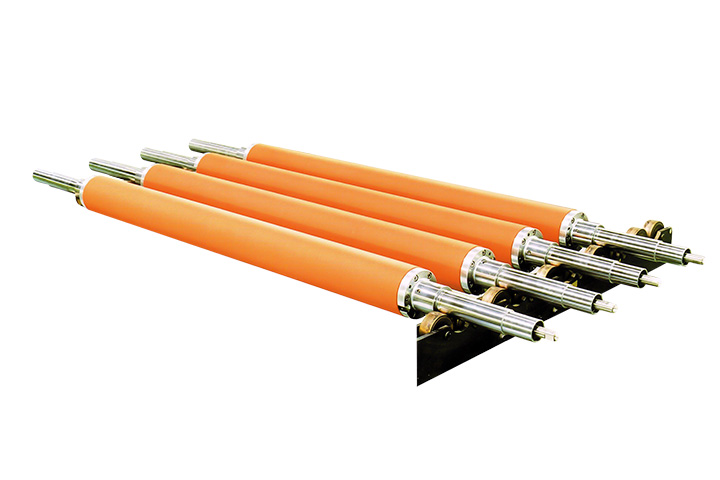

Features of Induction Heated Jacket Rolls

Wide Temperature Range

Induction heating draws on the magnetic field which is produced by the electric current applied to the induction coil. This system provides high temperatures and precise control in 1℃ increments from room temperature to 800℃.

Uniform Surface Temperature Distribution

The heat-pipe principle maintains a uniform temperature both across and around the roll. Temperature profile remains uniform whether or not a thermal load is applied.

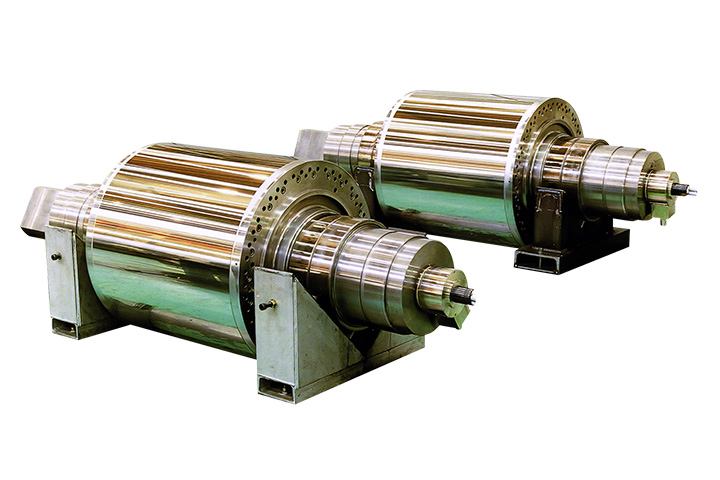

Compact, Easy-to-Use Electrical System

Since Jacket Rolls use only electricity as their heat source, there is no need for additional facilities or special construction. The equipment requires minimal space and is easy to operate.

Clean, Low Maintenance Operation

Because there is no oil, vapor or combustible material to leak, the work environment stays clean and safe. The temperature control system incorporates a microcomputer. The Jacket Rolls use no ignitable substances, so operation is also safe and low maintenance.